Understanding Concrete Block Machine Prices in Botswana

Introduction to Concrete Block Machines in Botswana

In Botswana, the construction sector is evolving rapidly, driven by urban expansion and infrastructure development. Concrete block machines, which produce essential building materials such as hollow blocks, paving stones, and solid bricks, are crucial to this growth. These machines are vital in creating durable structures and enhancing urban environments in cities like Gaborone, Francistown, and Maun. This article explores the impact of concrete block machine prices on the construction industry in Botswana, focusing on key aspects like machine types, production processes, and future trends.

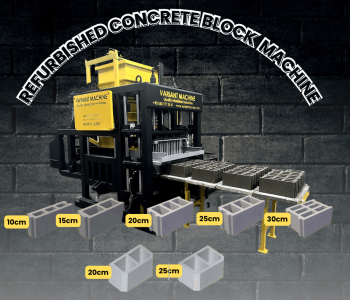

What is a Concrete Block Machine?

A concrete block machine is a piece of equipment designed to manufacture concrete blocks and bricks for construction. These machines use a combination of aggregate, sand, and cement, mixed with water to form concrete. The mixture is then poured into molds and compacted using vibration and press mechanisms to achieve the desired density and strength. The machine’s efficiency and the quality of the blocks produced depend on various factors, including the type of machine, its automation level, and the production process.

Factors Influencing Concrete Block Machine Prices

Concrete Brick Machine Costs: The cost of concrete brick machines in Botswana is determined by several factors, including the type of machine, its production capacity, and its level of automation.

- Manual Machines: These are the most cost-effective and are suitable for smaller-scale operations. They require manual labor for mixing, molding, and pressing, which makes them a budget-friendly option but less efficient for large projects.

- Semi-Automatic Machines: Offering a balance between cost and efficiency, semi-automatic machines reduce the need for manual labor while still involving some human intervention. They are ideal for medium-sized projects and regions experiencing moderate growth.

- Fully Automatic Machines: These machines are the most expensive but offer high efficiency by automating the entire production process. They handle mixing, molding, and pressing with minimal human intervention, making them suitable for large-scale projects in cities like Gaborone.

Types and Pricing of Concrete Block Machines: Concrete block machines come in various types, each with different price points:

- Manual Machines: These are suitable for small-scale operations and areas with lower construction demands. They are affordable but require considerable manual input.

- Semi-Automatic Machines: These offer a middle ground in terms of cost and productivity, making them a practical choice for growing cities like Francistown.

- Fully Automatic Machines: Though they come with a higher initial cost, fully automatic machines provide significant long-term benefits by increasing productivity and reducing labor costs. They are ideal for extensive urban projects.

The Role of Concrete Paver Machines and Their Pricing

Concrete Paver Machine Costs for Urban Development: Concrete paver machines are used to produce paving stones, which are essential for urban development and infrastructure. The cost of these machines varies based on their production capacity and technological features:

- High-Capacity Paver Machines: These machines are more expensive but are designed to produce large quantities of paving stones efficiently. They are particularly useful for large-scale projects in cities like Gaborone, where quality paving is crucial for roads, driveways, and public spaces.

Economic Impact of Paver Machine Prices: The pricing of concrete paver machines affects the overall cost of construction projects, particularly those involving extensive paving work. Investing in high-quality paver machines can lead to long-term cost savings by reducing manual labor and increasing production speed, which is essential for major infrastructure projects in Botswana’s urban areas.

Production Process and Cost Efficiency

Mixing Cement, Aggregate, and Concrete: Concrete block machines automate the mixing of cement, aggregate, sand, and water to create uniform and high-quality bricks. The efficiency of these machines impacts production costs and project budgets. In developing cities like Maun, understanding the cost implications of using concrete block machines is crucial for effective financial management.

Impact of Automation on Production Costs: Automation in concrete block machines reduces reliance on manual labor, leading to lower production costs and increased efficiency. Fully automatic machines, while involving a higher initial investment, offer substantial long-term savings through enhanced productivity and reduced labor needs. For construction projects in Botswana’s urban areas, investing in automated machinery can result in significant operational benefits.

Future Trends in Concrete Block Machine Prices in Botswana

Market Trends and Predictions: As Botswana’s construction industry evolves, so do the prices of concrete block machines. Advances in technology and shifts in market dynamics may affect machine prices, potentially providing opportunities for cost savings. Staying informed about these trends is important for making strategic purchasing decisions and managing project budgets effectively.

Opportunities for Cost Reduction: Technological innovations, such as energy-efficient designs and improved automation, may lead to more competitive pricing in the future. Keeping up with these advancements can help construction professionals in Botswana optimize their investments and reduce overall project costs.

Conclusion

Concrete block machine prices significantly impact the construction industry in Botswana. With varying costs based on machine type, production capacity, and automation level, understanding these prices is essential for effective project planning and budgeting. Whether in Gaborone, Francistown, Maun, or other cities, selecting the appropriate concrete brick and paver machines can enhance productivity and efficiency. By staying informed about market trends and technological advancements, stakeholders can make well-informed decisions that support the growth and development of Botswana’s urban infrastructure.