Exploring Pretoria’s Urban Landscape and Construction Industry

Historical Background

Pretoria, one of South Africa’s trio of capital cities, holds a rich historical narrative. Established in 1855 by Marthinus Pretorius, it rose to prominence during the South African Republic era. As South Africa’s administrative capital, Pretoria has played a significant role in the country’s historical development, evolving from a small settlement into a prominent urban center, reflecting both its historical roots and modern advancements.

Current Situation

Pretoria, functioning as South Africa’s administrative hub, is characterized by its blend of historical charm and contemporary progress. The city is home to numerous government offices and embassies, with ongoing development projects that highlight its role as a crucial political and administrative center. The continuous expansion and modernization efforts reflect Pretoria’s dynamic growth.

Recent Developments

Recent updates from Pretoria often highlight urban development, infrastructure enhancements, and economic progress. The city is undergoing various construction initiatives, including public service improvements and transportation upgrades. Challenges such as urban planning, housing shortages, and environmental issues are also prominent as the city adapts to its rapid growth.

Construction Sector in Pretoria

Overview

Pretoria’s construction sector is fundamental to its development, driving the growth of residential, commercial, and public infrastructure projects. The demand for construction materials and machinery is high, mirroring the city’s ongoing expansion and modernization.

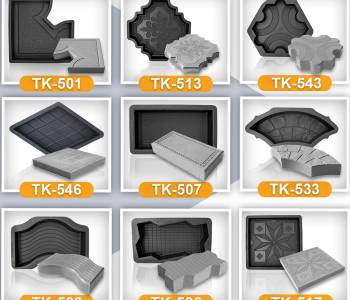

Concrete Block Machines

Concrete block machines are essential for producing building materials in Pretoria. Several types are used based on production needs:

- Wet Casting Machines: Create high-quality concrete blocks with a wet mix, known for their durability and precision.

- Dry Casting Machines: Suitable for blocks made with a dry mix, these machines offer efficiency and lower water usage.

- Manual Machines: Operated by hand, these cost-effective machines are ideal for smaller-scale production.

- Semi-Automatic Machines: These machines provide a balance between manual and automated operations, improving productivity with some manual input.

- Automatic Machines: Fully automated systems that ensure high efficiency and consistent quality for large-scale production.

Production Capacity: Concrete block machines in Pretoria vary from a few hundred blocks per day for manual types to thousands of blocks per day for fully automatic systems.

Concrete Batching Plants

Concrete batching plants are vital for large-scale concrete mixing:

- Stationary Plants: Fixed installations designed for high-capacity and consistent production, ideal for large projects.

- Mobile Plants: Flexible and easily relocatable, suitable for on-site mixing and smaller projects.

Production Capacity: Batching plants range from small setups producing a few cubic meters per hour to large facilities capable of several hundred cubic meters per hour.

Crushers

Crushers play a key role in material processing for construction:

- Mobile Crushers: Portable and versatile, these crushers are ideal for on-site material processing.

- Stationary Crushers: Fixed units used for continuous and large-scale material processing.

Types of Crushers:

- Cone Crushers: Ideal for secondary and tertiary crushing, providing fine and consistent product sizes.

- Impact Crushers: Used to produce high-quality aggregate with good shape and size distribution.

- Vertical Shaft Impact Crushers (VSI): Perfect for creating fine aggregates and manufactured sand.

- Jaw Crushers: Commonly used for primary crushing, handling large materials and offering high reduction ratios.

Pricing Considerations

Concrete Block Machine Pricing in Pretoria

The cost of concrete block machines in Pretoria is influenced by:

- Machine Type: Pricing differs between manual, semi-automatic, and fully automatic machines based on their level of automation and features.

- Production Capacity: Higher capacity machines generally have higher costs.

- Brand and Model: Different brands and models offer varying features and quality levels, impacting the price.

Stationary Concrete Batching Plant Pricing in Pretoria

Factors affecting the pricing of stationary concrete batching plants include:

- Capacity: Larger plants with higher output capacities tend to be more expensive.

- Features and Technology: Advanced features and technology can increase costs.

- Installation and Maintenance: Costs for installation and ongoing maintenance impact the overall price.

Crusher Pricing in Pretoria

The cost of crushers in Pretoria is determined by:

- Type of Crusher: The choice between mobile and stationary crushers, and the specific type (cone, impact, VSI, jaw) affects pricing.

- Capacity and Size: Larger crushers with higher processing capacities are generally more expensive.

- Brand and Quality: High-quality brands and models often come at a premium.

Conclusion

Pretoria’s development as a major administrative capital reflects its historical significance and modern progress. The city’s construction sector is crucial to its ongoing growth, supported by a range of machinery including concrete block machines, batching plants, and crushers. Understanding the factors that influence machinery pricing-such as type, capacity, and technology-is essential for making informed decisions. As Pretoria continues to evolve, these insights will help stakeholders effectively navigate the city’s dynamic landscape and contribute to its future success.